Automatic Machine Production

- Home

- Automatic Machine Production

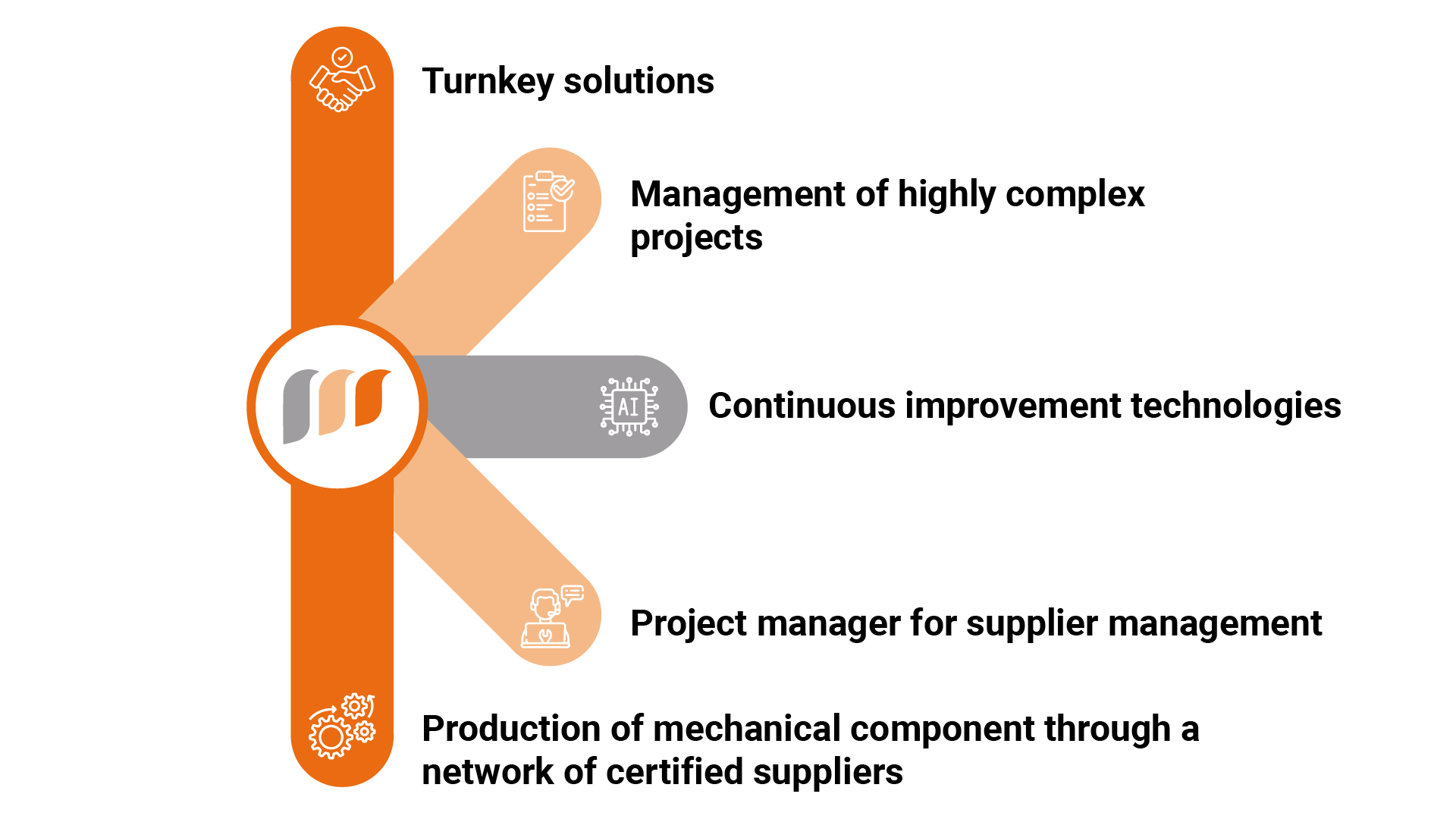

Thanks to our extensive experience in the industrial automation sector and close collaboration with major Packaging industries, Infomotion has expanded its production capabilities to deliver high-quality mechanical services as well.

Starting from the project provided by the client, we carry out mechanical assemblies of entire machines and industrial plants with meticulous care and precision.

This activity, combined with Infomotion’s range of services, allows us to provide complete systems up to their commissioning and testing at our facility.

Our spaces

We have a 4000 square meter production area, equipped with overhead cranes and heavy-duty load handling systems.

The entire production area is organized into zones dedicated to the assembly of mechanical components and the assembly of complete machines.

Each zone is equipped with workbenches and appropriate tools to carry out activities safely and efficiently. Access to multimedia workstations is available for viewing 3D drawings and projects, as well as other documentation essential for the implementation of the systems.

Our experience

We are capable of handling highly complex systems both technically and logistically, managing machines with over 10,000 components.

During the assembly phases, our experienced and professional technicians provide analysis and evaluations to suggest improvements that contribute to achieving higher quality in the final result, with a particular focus on Design for Assembly (DFA) aspects.

Our team serves as a crucial point of reference and collaboration for our client’s technical department. Additionally, we engage with various stakeholders within the client’s organization involved in the project, such as purchasing, production management, and quality assurance departments.