In 30 years of activity, we have specialized in the design of ELECTRICAL DIAGRAMS, in the realization of ELECTRICAL CONTROL CABINETS, and ON-BOARD INSTALLATION for industrial automation.

Our designers, installers, and testers are constantly updated, in order to program and install the latest generation systems.

We are able to develop diagrams designed with EPLAN P8 and SPAC, particularly useful for optimizing the entire automation process.

Both the planning and the realization of the wiring of our electrical panels are carried out according to international regulatory standards. For us, who work for major manufacturers of automatic machines, it is essential to meet all regulatory requirements, such as IEC and, for the North American market, UL/CSA.

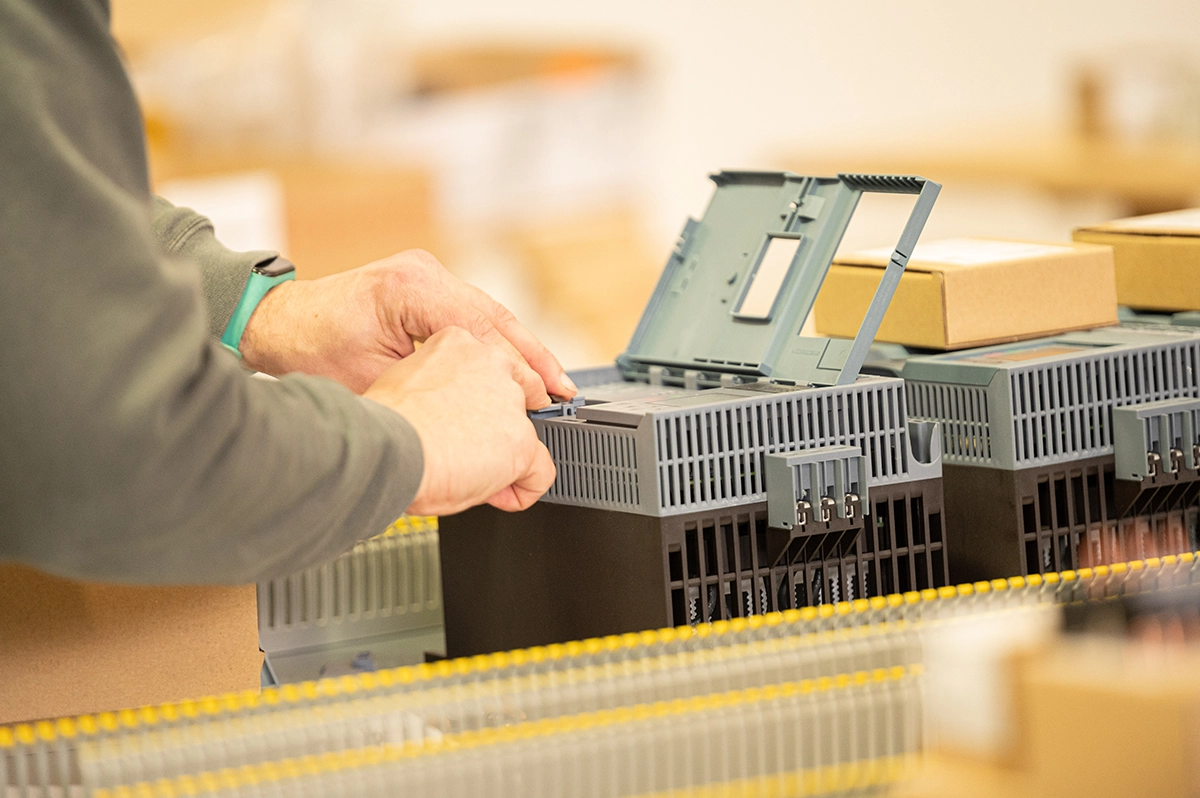

INDUSTRIAL ELECTRICAL PANELS FOR AUTOMATION

Always attentive to even the smallest detail, we produce industrial electrical panels for automatic machines and systems, mantaining the standards of the highest specialization in the following sectors:

We work closely with our costumers and partners to find the right control solution for their needs. Many years of experience have allowed us to develop a consolidated reliable process. Our work of design and production of electrical systems is constantly monitored and updated with respect to the latest regulations and methods.

DESIGN OF ELECTRICAL PANELS

The basis of the process is undoubtedly the design. Our service consists in designing plant hardware. This includes the development of wiring diagrams in compliance with current regulations. In the design phase, the specifications draw up by the end customer are scupulously followed. Alternatively, the choice is to use hardware produced with the latest technologies, the result of continuous research on the market, so that increasingly performing and cutting-edge components can be identified.

HARDWARE PRODCUREMENT

We are able to supply all the hardware components that emerged during the design phase, both from our network suppliers and directly from the manufacturers. With various manufacturers we have access to purchase for years.

ELECTRICAL PANELS COMPLIANT WITH MULTIPLE STANDARDS

Once the design is finished, we move on the actual realization of the panels, starting from the assembly and then moving on to the wiring of the components, which are necessary for the correct functioning of the entire system. Construction and all wiring harnesses are carried out according to IEC standards and, for the North American market, UL/CSA.

INSTALLATION ON-BORAD MACHINE

At this point we are able to take care of the installation of the systems on the machine, as well as the wiring of entire production lines. Therefore we provide for the laying and subsequent wiring of the cables, from the cabinet to the individual sensors or actuators positioned on the “edge of the machine”. Therefore, we at Infomotion take care of every detail up to the final and functional tests.

FINAL TESTING

At the endl of the installation, the final test of the entire system takes place. This task is carried out by our specialized technicians, who deliver to the customer a detailed report on the tests performed. On the customer’s indication, tests are also periodically carried out with the final product.

DOCUMENTATION

At the end of the production process, the design documentation is provided to accompany the electrical panel for the automation of the machine, which includes: